Project Description

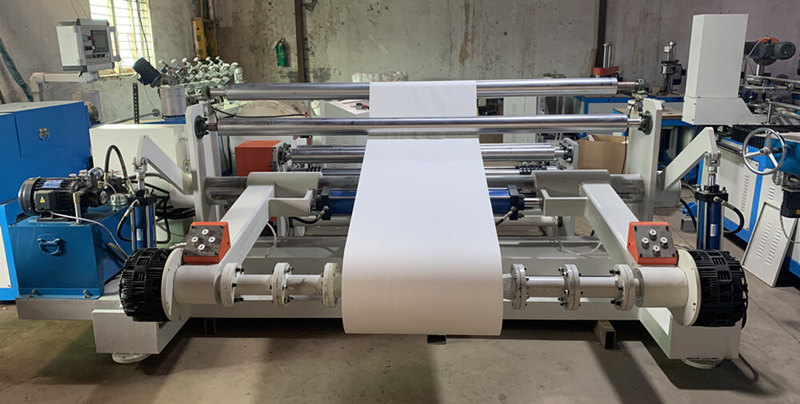

Jumbo Paper Roll Slitter Rewinder Machine SY-QC1600

Application:

Suitable for all kinds of kraft paper, tea paperboard, grass paperboard, calico and art paper cutting

Feature:

- Two blades cutting; thicken blade;

- The two side of the paper will be smooth after the cutting, without any burring;

- Tray paper will be tidy with two sides feat;

- With the computer rectified system and it can rectified automatically.

- All the operation will be finished on the panel with ease operation;

- With high capacity, the single machine can be provided for three sets of reel-pipe machine;

- S.S structure body; beautiful performance;

- Pneumatic discharge with easy operation

- Automatic tension control

Photo:

Technical Parameter:

| Jumbo roll width | 1000-1600 mm |

| Un-winder diameter | 1300 mm |

| Re-winder diameter | 1300 mm |

| Slitting speed | 0-150 m/min |

| Slitting range | 60-600 g |

| Min slitting width | 25 mm |

| Re-winding method | stalk involution |

| Blade quantity | 21 pairs |

| Load paper roll | Pneumatic way |

| Speed adjust | Transducer |

| Power supply | 380V 3phase |

1 Q:What is the machine warranty?

A: One year. We will provide maintenance support for any issue with the equipment. If the equipment are still under warranty, we will replace and repair the faulty parts free of charge and buyer will only need to pay for the shipping or air charges. In general we are able to ship the faulty party that are in stock within 1 day.

2 Q:What is the delivery time?

A:15-30days after get the payment.

3 Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

4 Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

5 Q:What’s the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

6 Q:Who is going to install the equipment?

A:Generally, as a buyer you will visit our factory for equipment training and installation but if needed we could also visit buyer’s factory. Buyer only need to pay for return air ticket and lodging expenses.

7 Q: Do you accept factory visiting?

A: We are highly greeting for your visiting.

Download here:

Share Our Product, Choose Your Platform!

Why Choose us

Professional R&D Team: Over 8 years experience with a top engineer team supported

Outstanding Quality: Only choose famous brand main electric components for production

ISO CE Approved: Professional certification bodies certify that the machines are of high quality

More Cardboard Tube Packaging Machine For Your Choice

China Service office

Mr Sam Dong

sales@roundboxmachine.com

+86 13736318590

Russia Service office

Mr Дмитрий Дубков

d_dubkov@mail.ru

+7 831 27580102

Thailand Service office

Mr Thakol Yajai

info@technotestsystem.com

+662 130 6900

Australia Service office

Mr Neil Phillips

neil@ercpackaging.com.au

+61 03 9354 2022